News

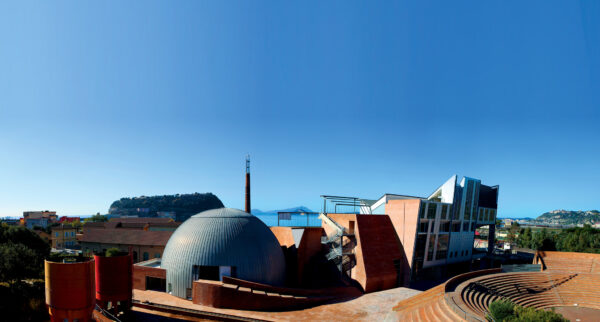

LBBC to exhibit in Napoli, Italy at the EICF Conference and Exhibition 12 – 15th May 2024

LBBC Technologies are the leading manufacturer of mould dewaxing and ceramic core leaching autoclaves for the investment casting industry. Our extensive experience working with investment foundries ha …

LBBC team of Enterprize Advisers are helping bridge the gap between education and working life.

Greater engagement between schools, colleges and local employers is at the heart of the Leeds Manufacturing Festival and its aim of promoting the opportunities that careers in the sector present for f …

LBBC Technologies will be exhibiting at ICI 70th Technical Conference & Expo, Pitsburg next month

LBBC Technologies will be exhibiting at ICI 70th Technical Conference & Expo, Pitsburg August 13 – 16, 2023. Our expert capabilities are cross functional from project management and solid model de …

LBBC Group showcase company and meet the next generation of Engineering.

L-R Adam Benn, LBBC Beecwood, James Moon, LBBC Technologies LBBC Group met the next generation of Engineers at the Leeds Manufacturing Festival Showcase yesterday at Leeds City College. James Moon, LB …

LBBC Technologies successfully pass BSI audit for the ISO9001 accreditation

LBBC Technologies have successfully passed the BSI audit for the ISO9001 accreditation. The BSI auditor was extremely complimentary of the individuals she had met, and of the company stating that she …

LBBC Technologies will be exhibiting at EICF Conference and Exhibition, Bregenz 7 – 10 May 2023

LBBC Technologies will be exhibiting at EICF Conference and Exhibition, Bregenz 7 – 10 May 2023 talking about the latest developments with the Dewaxing Boilerclave® and the core removal systems. Havin …

Great success at World Conference Investment Casting conference last month

LBBC Technologies showcased their latest model LC450HPHT ceramic core removal autoclave system on at the World Conference Investment Casting show last month. It was great opportunity to reconnect with …

LBBC Technologies demonstrating equipment and introducing Connected Support at World Conference Investment Casting show in California

LBBC Technologies will be demonstrating equipment and introducing Connected Support at the World Conference Investment Casting show in California next month. Our expert capabilities are cross function …

Categories

Archives

- April 2024

- August 2023

- July 2023

- March 2023

- January 2023

- December 2022

- September 2022

- July 2022

- March 2021

- October 2020

- October 2019

- September 2019

- April 2019

- January 2019

- December 2018

- September 2018

- July 2018

- January 2018

- August 2017

- February 2017

- January 2017

- November 2016

- September 2016

- August 2016

- June 2016

- May 2016

- March 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- April 2015

- March 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- April 2014

- March 2014

- January 2014